|

In 2017, Holtec submitted the licensing application for establishing a Consolidated Interim Storage Facility (CIS) that we plan to develop in collaboration with our local partner ELEA, LLC (a regional business alliance in South-east New Mexico). This facility, named HI-STORE CIS, will store the nation’s used fuel packaged subterranean cavities employing our tried and tested HI-STORM UMAX technology. The loaded canisters from nuclear plant sites across the country will be hauled in our universal transport cask [HI-STAR 190, licensed by the NRC this year]. We expect NRC’s approval of HI-STORE CIS facility by 2021. We also hope that Congress and the DOE will embrace the solution developed by our (private) initiative to end the used fuel management imbroglio that has stunted the rise of nuclear energy in America for well over three decades.

We welcomed the national nuclear operators of Slovenia and Brazil amongst the ranks of our esteemed international customers. Holtec Arabia based in Dubai, and Holtec Africa based in Johannesburg, began active operations.

Started in 2010, the R&D effort on our small modular reactor (SMR-160) program forged ahead in 2017 despite the continued absence of any federal funding. On the technology front, Holtec manufactured the first batch of multi-purpose canisters to store used fuel from Russian-origin reactors (VVERs).

Innovation, which is the mother’s milk for our corporate prosperity, remained a core company endeavor, symbolized by 16 new US patents granted to the Company in 2017. In recognition of our innovations, our CEO was elected a Fellow of the National Academy of Inventors, and was inducted in the “Walk of Fame” of the University City Science Center in Philadelphia.

A giant stride in life extension of multi-purpose canisters was made in collaboration with the Southern California Edison Company by the development of a laser peening process for the heat sensitized regions of multi-purpose canisters. All 75 canisters being manufactured for the Edison’s San Onofre’ nuclear plant are being peened at the Holtec Manufacturing Division using this pioneering technology.

|

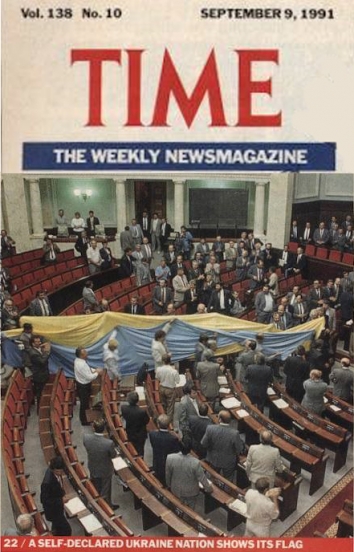

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

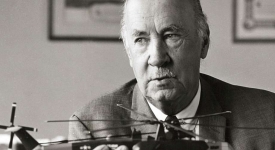

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

Ten USUBC Historic Full Page Ads in the Kyiv Post

Ten USUBC Historic Full Page Ads in the Kyiv Post

Holtec International, Marlton, NJ,

Holtec International, Marlton, NJ,