Featured Galleries CLICK HERE to View the Video Presentation of the Opening of the "Holodomor Through the Eyes of Ukrainian Artists" Exhibition in Wash, D.C. Nov-Dec 2021

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

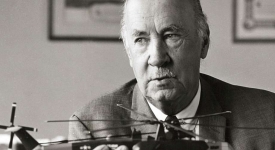

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

Ten USUBC Historic Full Page Ads in the Kyiv Post

Ten USUBC Historic Full Page Ads in the Kyiv Post

Helium Dreams. A new generation of airships is born.

The New Yorker, New York, NY

The New Yorker, New York, NY

Jeanne Marie Laskas

Mon, Feb, 25, 2016

Much of the world has no access to paved roads. Vast cargo-bearing airships could reach places that planes and trucks can’t.

Igor Pasternak started thinking about airships when he was twelve. Back then, in the nineteen-seventies, he loved rockets. One night, he was curled up in the soft green chair that doubled as his bed, in the two-room apartment where he lived with his parents, his little sister, and his grandmother, in the city of Lviv, in western Ukraine. He was reading a magazine aimed at young inventors, and he came across an article about blimps. He saw old photographs of imposing wartime zeppelins and read about another kind of airship, which had never made it off the drawing board: an airship that carried not passengers but cargo. It would be able to haul hundreds of tons of mining equipment to remote regions in Siberia in one go, the article said—no roads, runways, or infrastructure needed. Just lift, soar, and drop.

Where are all the airships? he asked himself. The world needs airships.

THE BLIMP-MAKER

Igor Pasternak, the C.E.O. and chief engineer of Worldwide Aeros, is fulfilling his lifelong dream of creating aircrafts that are lighter than air.

His parents, civil engineers, thought that he would move on to more practical interests. Instead, Igor drew pictures and worked on equations. In high school, he formed an airship club and was invited to present his designs to a gathering of aerospace engineers in Moscow; at Lviv National University, where he studied civil engineering, he established an airship-design bureau. By 1986, he had started a business manufacturing tethered blimps for advertising—one of the first private aerospace companies permitted under Mikhail Gorbachev’s perestroika reforms.

In 1994, at the age of twenty-nine, Pasternak brought the business to the United States. He knew no English. He knew blimps. He rented an office in New York City, hired a translator, and proclaimed himself an American blimp-maker, but he found no customers. He called his sister, Marina, who was also an engineer and had immigrated two years earlier, with the rest of the family. They lived in California, and to pay the rent they had resorted to gluing envelopes for cash. Castle Air Force Base, about two hours south of San Francisco, had recently been scheduled to close, and the hangars that had once housed B-52 bombers were available for lease. Pasternak set up shop there, with Marina, their father, and a few friends from Lviv. The first blimp they built, the Aeros 50, was a seventy-eight-foot one-seater, which they sold to an Atlanta company to use for advertising during the 1996 Paralympic Games. “We are getting there,” Pasternak told Marina.

By 2000, they had developed the 40B Sky Dragon, which featured an electronic steering mechanism, automated pressure control, and an optional set of spotlights inside the hull, to create a dazzling “night glow” effect. The Sky Dragon was a hit. With a team of two dozen workers, Pasternak built several blimps, at more than two million dollars apiece, for use by companies including MasterCard, Spalding, the Malaysia tourism board, and, in Germany, Commerzbank. “We are just beginning,” he said to Marina. He told her that they would move beyond advertising blimps—way beyond.

A blimp is just one type of airship, usually a small one, and always nonrigid, meaning that it has no structural hull; its shape is maintained by the pressure of the lifting gas within. It’s basically a balloon with a rudder and a means of propulsion. The first one was built in 1852, by the French engineer Jules Henri Giffard; it was a hundred and forty-four feet long, with a propeller and a three-horsepower steam engine. In 1900, in Germany, Count Ferdinand von Zeppelin built something much larger and stronger, adding a rigid aluminum framework—long internal girders, attached to flexible rings, that formed a kind of rib cage. A number of discrete cells, each filled with hydrogen, fit inside the rib cage, and the entire ship was covered with fabric. The first of these, the LZ 1, was four hundred and twenty feet long, and Zeppelin kept making them bigger. He started the world’s first airline company, DELAG (Deutsche Luftschiffahrts-Aktiengesellschaft), and by 1914 the service had made more than fifteen hundred flights, transporting upward of ten thousand people. Before long, Italy, Great Britain, the United States, and other countries began building airships.

The gas cells of many of the early zeppelins were made from so-called goldbeater’s skin: cow intestines beaten to a pulp and then stretched. It took two hundred and fifty thousand cows to make one airship. During the First World War, Germany and its allies ceased production of sausages so that there would be enough cow guts to make zeppelins from which to bomb England. Advances in fabric-manufacturing technology—including the invention, in 1839, of vulcanized rubber, by the American merchant Charles Goodyear— prompted a frenzy of airship innovation. In the early nineteen-thirties, the U.S. Navy built two “flying aircraft carriers,” the Akron and the Macon, whose bellies could open to release fleets of F9C Sparrowhawk fighter planes. (The ships crashed, in separate storms, before proving their battleworthiness.)

Then airships went away. On May 6, 1937, the Hindenburg exploded over Lakehurst, New Jersey, in a ball of fire that killed thirty-six passengers and crew members; the tragedy was captured on film. The idea of people floating comfortably beneath a container of explosive hydrogen became, in an instant, ridiculous. (Modern airships use only helium, which is not flammable.) Fixed-wing aircraft, such as Pan American Airways’ speedy “flying boats,” became increasingly popular and more economical. A few of the airship engineers I talked to lamented the fact that, until 1999, when a compilation entitled “Airship Technology” was published, the only textbook available to them on airship engineering was Charles B. Burgess’s “Airship Design,” which came out in 1927.

Airship designers eventually abandoned the idea of carrying passengers and embraced the notion of carrying cargo, which is achieved only inefficiently by rail, roads, and sea, and isn’t achieved at all in remote areas. A few early projects gained traction. In the nineteen-seventies, William Miller, a former Navy fighter pilot in New Jersey, tested a ship with an aerodynamic deltoid shape, called the Aereon 26. (John McPhee wrote about Miller for this magazine in 1973.) But Miller ran out of funds after just one test flight. Everywhere, the return of the airship kept being the almost return of the airship. Merely creating a prototype of a cargo airship required enormous capital, and prospective buyers were scarce. In Germany, Cargolifter A.G. got as far as building the world’s largest freestanding building, more than a thousand feet long, in which the company planned to construct a helium-filled semirigid cargo hauler. But Cargolifter filed for bankruptcy in 2002; the hangar, outside Berlin, was later turned into Tropical Islands, Europe’s largest indoor water park.

A new generation of airship engineers, some backed by significant government and private investment, is convinced that, given new technologies and new materials, the public can be sold on airships. Last March, the U.S. House of Representatives set up the bipartisan Cargo Airship Caucus, with the goal of accelerating development. In recent years, the aerospace heavyweights Boeing and Northrop Grumman have developed airships; Russia, Brazil, and China have built or conceived prototypes, and Canada has designs for a few of them, including the Solar Ship, which looks like a bloated stealth bomber, with solar panels spread across the top of helium-filled wings. All are racing to be first to corner a cargo market that may be worth billions. Three projects are currently attracting the most attention: the Airlander 10, which is scheduled to launch next month, in England; Lockheed Martin’s LMH-1; and Pasternak’s Aeroscraft, the machine he first envisaged as a boy in Lviv.

Every airship engineer I talked to asked me to disregard the Hindenburg. “When we first started this, there was a lot of giggle factor,” Bob Boyd, the program manager for Lockheed’s airship, told me. “The world thought this was old technology: those airships, ha ha ha. And everybody would mention the H-word—we don’t say the H-word—and it was, like, O.K., but that’s not the point.”

The point, which Boyd makes in a promotional video, “The Road Not Needed,” is that “more than two-thirds of the world’s land area and more than half the world’s population has no direct access to paved roads.” Modern airships could take off and land with the precision of helicopters and deliver entire warehouses, drilling rigs, or fully stocked factories. Today’s airship designers share a vision: magnificent amounts of trucking going on in the sky—regular convoys of enormous airships carrying timber, coal, wind turbines, prefabricated homes, or an entire summer harvest, puttering gently along at about a hundred miles an hour, ten thousand feet over our heads.

Airships are unlike other engineering pursuits. The science is about floating through clouds, about complex negotiations involving gravity and the breeze. It’s as if math married romance. It attracts certain people. Enthusiastic people.

“It’s an addiction,” Pasternak told me. “I cannot do nothing else.” His company, Worldwide Aeros, now employs more than a hundred workers and is headquartered in Montebello, California, six miles south of Los Angeles, where Pasternak lives with his wife, Sosik, his eleven-year-old son, Matthew, a dog named Blue, and a bird named Tim. He is fifty-one and five feet five, and he speaks with a heavy Russian accent; he has a thick and bouncy mop of silver curls, and favors pin-striped suits and cherry-red ties. Some years ago, he relocated his blimp-manufacturing operations to a pair of hangars on a former naval airbase in Tustin, about thirty miles from his office. On a hot summer day in 2014, we rode out there in the back of his luxury S.U.V., a customized black Yukon Denali, the seating arranged parlor style. The hangars, gigantic elongated domes, were built in 1942, to store war blimps. As we approached, they emerged like ancient pyramids from the scrubby desert, wobbling in the waves of heat.

Inside Hangar 1 was a Sky Dragon—cloud-white, a hundred and fifty-two feet long, with a pointy nose, four stabilization fins jutting from the rear, and a royal-blue gondola with a two-wheeled landing gear underneath. “This one is already finished,” Pasternak said. The Sky Dragon is still his best-seller; the 40B evolved into this model, the 40D, which features a glass cockpit and a thousand-pound payload capacity for radar-surveillance equipment. On a single day, September 11, 2001, the market for Pasternak’s advertising blimps collapsed and the market for surveillance blimps was born. “One day, we wake up and we become defense company,” he said.

In the hangar, two workers wearing black Aeros T-shirts were getting the Sky Dragon ready for a dedication ceremony, where the guests would include four members of Congress, a priest who would sprinkle holy water, and a mariachi band. The blimp would then be flown to Tijuana, where local officials planned to use it to inspect hundreds of miles of oil pipeline for leaks and for any signs of mischief. Thailand had recently bought a 40D for patrolling its borders, and Pasternak was working on a deal to sell a surveillance package to Ukraine, so that its military could keep an eye on the Russians.

“I can’t believe I spent seven million dollars on tights.”

“I can’t believe I spent seven million dollars on tights.”

Pasternak’s surveillance-airship business is worth millions, but wealth was never his goal. “It’s all about the cargo airship,” he said. His cargo prototype, the Dragon Dream, was in Hangar 2, on the other side of the base. Two hundred and sixty-six feet long—nearly the length of a football field—and ninety-six feet wide, the Dragon Dream was the largest rigid airship built in the U.S. since the nineteen-thirties. And yet it was just half the size of Pasternak’s proposed masterpiece, the Aeroscraft. The Aeroscraft will come in three sizes. The ML866 will be five hundred and fifty-five feet long and able to carry sixty-six tons of cargo. The ML868 will be about thirty per cent larger, with a capacity of two hundred and fifty tons. And the ML86X will be nine hundred and twenty feet (nearly three football fields) long, two hundred and fifteen feet (more than the Tower of Pisa) high, three hundred and fifty-five feet (two Boeing 747s) wide, and able to carry five hundred tons. (The letters “ML” in the names are a tribute to Marina and to a friend, Levon, who died in 2000, in an accident in the hangar.) To get an idea of the scale of the ML86X, imagine a flying, elongated Houston Astrodome hauling a hundred and fifty elephants. The cargo would sit inside the enormous belly of the ship; there would be no danger of dropping it on people below.

The biggest challenge in using lighter-than-air technology to lift hundreds of tons of cargo is not with the lifting itself—the larger the envelope of gas, the more you can lift—but with what occurs after you let the stuff go. “When I drop the cargo, what happens to the airship?” Pasternak said. “It’s flying to the moon.” An airship must take on ballast to compensate for the lost weight of the unloaded cargo, or a ground crew must hold it down with ropes.

Pasternak has thought about this problem for decades, studying submarine technology and the swim bladders of bluefish. Eventually, he invented a system he called COSH, for “control of static heaviness,” based on an obvious principle: a helium-filled airship goes up, so an airship filled with air (which is heavier than helium) should go down. The trick is to swap out one gas for the other on command. With COSH, helium is compressed and sent to storage tanks inside the airship. To ascend, the pilot lets the helium fill the main chamber; to descend, the helium is compressed and sent back into the tanks, enabling the chamber to fill with air.

In the years after September 11th, the Department of Defense spent more than a billion dollars on at least eight airship programs, with an eye toward surveillance, as well as haulers that could move troops and supplies to remote parts of the globe. COSH impressed the Defense Advanced Research Projects Agency, and in 2005 it gave Pasternak three million dollars to develop the idea. In 2010, it added fifty million dollars so that he could build the Dragon Dream. In creating the ship’s flexible skeleton, he was inspired by the structural design of the Eiffel Tower, and he attached vector-thrust engines, which can aim in any direction. Instead of wheeled landing gear, he chose air-cushioned feet, like those on a hovercraft, so that the ship could land on virtually any surface, and he installed reversible fans in the feet, which would provide suction and allow the ship to stay on the ground.

On July 4, 2013, the Dragon Dream was ready to fly. People on the highway pulled over and snapped pictures of the strange lozenge-shaped craft, glinting silver, cruising a few hundred feet in the air. It landed softly, the pilot activated the COSH system, and the test cargo—a wooden crate filled with five hundred pounds of lead pellets—was unloaded. The ship stayed exquisitely still. “What we proved is that I can deliver the cargo, and I can stay on the ground,” Pasternak told me. “This was: yes, I really can create the cargo airship.”

He invited investors to view his prototype, and he was eager to get moving on orders. One morning in October, 2013, a little before eight, the phone in his Montebello office rang. There was a problem, one of the employees in Tustin told him: the roof of Hangar 2 had collapsed. Without warning, the long beams of Douglas fir that supported the roof had fallen seventeen stories, crashing through the rear of the Dragon Dream, crushing fins, demolishing an engine, and smashing the ultralight carbon honeycomb fibre trusses. When we pulled up to the hangar, the wreckage was still there, months later. “So this, you see, this is what happened,” Pasternak said. Sheets of shredded silver skin flapped over a tumble of shimmering bones; fibre-optic cables sprouted every which way. “This is what happened.”

Lockheed Martin is the Pentagon’s largest aircraft supplier, and its Skunk Works operation, a windowless complex in Palmdale, California, about sixty miles northwest of L.A., is where top-secret projects like the U-2 spy plane, the SR-71 Blackbird, and the F-117 Nighthawk were developed. A wide underground tunnel connects a hive of giant hangars. Recently, inside one of them, Bob Boyd showed me a puffy white airship the size of a dairy barn. It was a half-scale demonstration model of the LMH-1, the airship that the company has been quietly developing for the past twenty-five years. It was unveiled last July, at the Paris Air Show, and introduced as a “hybrid airship,” ready for order through Hybrid Enterprises, a private reseller, for forty million dollars.

“Take a look,” Boyd said. “Everyone wants to punch it.”

Boyd is tall, with a soft build, sloped shoulders, and a complexion suggesting a life indoors. He had to shout over the whir of blowers and the racket of machinery echoing from other regions of the hangar. When he came to Lockheed Martin, in 1997, he was like a lot of young aerospace recruits, eager for speed and supersonic excitement. But when the fledgling airship team showed him some drawings he was hooked. “Once you understand, it’s, like, Oh, we have to have this,” he said. He described long nights at home factoring helium and buoyancy into engineering equations. All of the airship designers I met had, at some point, experienced a similar awakening. Airships made sense. Airships deserved billions of dollars of investment—whatever it took to get them flying.

Boyd again invited me to punch the airship, so I made a fist and gave it a jab. It was softer than a tire, the walls thin and shiny. The hull had a trilobe construction and looked like three long flattened blimps fused together. Four engines, each powering its own propeller, were mounted on the sides and the rear of the hull, where stabilization fins formed a truncated tail. Hybrid airships combine lighter-than-air lift with more conventional aircraft technology. Lockheed’s uses helium for only about eighty per cent of its lift; the rest comes from the aerodynamic form of the body. Its weight is intended to make it easier to control on the ground.

Boyd escorted me to the back of the LMH-1, where he positioned a yellow stepladder just beneath the point of entry, a gathering of hull material that was bunched around a valve and secured with a heavy rope. The rope and the valve and the bunching gave the impression of a party balloon on a gigantic scale. An engineer from the team untied the rope. That day, the airship was filled with air, as is typical for routine maintenance checks.

“You can leave your shoes here,” Boyd said, and he went up inside the hull of the airship, hoisting himself through the opening, which had turned into a madly flapping tube. He told me to move quickly; someone would close the valve behind us. Inside, it was dark, and it was slippery, like being in a bouncy castle. Boyd had brought a flashlight, and he shone its beam along the seams of the ship and then up and down the internal structure, ligaments of fabric set strategically and running the length of the craft. He handed me a swatch of the material. It felt like canvas coated with rubber, thin as a patch that one might sew onto a pair of jeans.

“That stuff will stand twelve hundred pounds per linear inch,” Boyd said. “So that little two-inch strip would lift a ton.” Airships don’t pop, like balloons; the pressure isn’t great enough. Holes, which are common, are easily fixed. Advances in material technology made nonrigid airships the better design choice, in Boyd’s view. Several airship designers told me that rigid designs like Pasternak’s are expensive, heavy, and considered old-school. Nonrigid is simpler, Boyd told me: you can construct the whole thing flat on the ground—no scaffolding needed—and simply inflate it when you’re done.

“Now we have another surprise,” he said. He aimed the flashlight at the entry valve, and we went with a whoosh back through the flapping tube and onto the stepladder. A group of Lockheed officials in dark suits were waiting for us, grinning awkwardly. “Here are your shoes,” one said.

“Let’s go fly,” another said, and we all went to an adjacent part of the hangar and stood at the controls of an LMH-1 simulator. Tall screens that wrapped around us displayed a cartoon image of Edwards Air Force Base, brown and smooth; a pilot named J.B. was pretending to fly us over it.

“It’s on?” one of the officials said. It was not apparent that we were moving.

“We’re headed northbound, from Palmdale,” J.B. said. “This is where Chuck Yeager took off to do the speed-of-sound run. Strapped into X1 underneath a B-29.”

Everyone more or less agreed that being “aloft” in the LMH-1 was not like that.

“We’re flying?”

Gradually, as I watched the cartoon desert, I began to see that our simulated airship was, in fact, simulating flight.

“It’s more like standing on top of a building than like being in an airplane,” Boyd said. “It’s just very, very mellow.”

J.B. demonstrated the simplicity of the controls. “When things go bad, just let go,” he said. Weather wasn’t a concern for the modern airship pilot; onboard satellite systems permit him to avoid storms, fly around them, or hover somewhere and wait.

“Now you’re doing a blazing thirty knots,” one of the engineers pointed out. That’s just under forty miles an hour; the LMH-1 would top out at about ninety.

“The bottom line is, you’re not in a hurry.”

“It’s like the least stressful job ever.”

“You’ll get a lot of reading done.”

“There. Just landed.”

“We landed?”

The LMH-1 was equipped with an air-cushioned system that looked identical to the landing gear on Pasternak’s Dragon Dream. In fact, all of the leading prototypes in the race to bring back the airship are chimerical combinations of the same technologies. (Lockheed Martin claims to have invented the air-cushioned landing system and the multilobe hull.) Over the years, most of the airship designers I talked to had competed for the same Defense Department funding, and engineers skipped in and out of one another’s projects, their lips supposedly sealed but probably not, and so there were squabbles, lawsuits, and settlements. “I know all those people, and they know me,” Boyd told me, sounding fatigued.

I asked Boyd about Pasternak’s buoyancy-control system, which had just shown up in a new design for the Russians’ airship, the Atlant. He said he thought it was a decent idea: “It works. But it costs a lot. It weighs a lot. So you’ve got to make a trade. Do I believe that’s important enough to put it on board?”

Boyd said that for ballast the LMH-1 could make do with a water truck at the landing site: the ship could drop off its load, fill the emptied cargo space with water, and be good to go. “Keep the weight down, keep the cost down—for us, it’s all about cost,” Boyd said. He expects the LMH-1 to become certified by the Federal Aviation Administration by the end of 2017, paving the way for delivery in 2018.

What’s still unclear is who will receive the delivery; the enthusiasm of airship builders has so far not translated into airship buyers. William Crowder, a senior fellow at the Logistics Management Institute, a nonprofit consulting firm that works with both civil and defense agencies, has been tracking the development of the modern airship for twenty years. “You’ve got to operate with a profile where you can deliver cargo faster than an ocean liner, but much more cost-effectively than an airplane,” he told me. Crowder calculates that cargo airships make sense economically only when they’re moving massive quantities of cargo—not twenty tons, what the LMH-1 could haul, or even sixty-six tons, the capacity of Pasternak’s smallest Aeroscraft, but more on the order of five hundred to a thousand tons, the payload of a super-jumbo carrier.

“You want to put a hospital into Africa?” Bruce Dickinson, the company’s lead investor, said to me. “You put the whole hospital in the inside of this—whoosh. Start the generator. ‘Here’s your hospital, buddy!’ Job done. You know? You can just plunk the vehicle straight down on the farm, load it with fifty tons of green beans or whatever, and twenty-four hours later you land right next door to the processing plant. It’s a global conveyor belt. And water! With these vehicles, you could drop off a twenty-ton slab of water that is clean, drinkable, to an African village. It’s astonishing what you can do that you just can’t do with anything else. Shit, you can do that with it? Wow, you can do that with it? Seriously fantastic!”

Clean-shaven, with dimples and loosely cropped silver hair, Dickinson is better known to a certain fraction of the world as the lead singer of the heavy-metal band Iron Maiden. He is also a jet-rated pilot who flies the band’s 747, Ed Force One, during world tours, and he is a co-owner of Cardiff Aviation, an aircraft-maintenance facility and pilot-training company in Wales. When we spoke, we were standing in front of the Airlander, which was parked in its hangar, at Royal Air Force Cardington, where it was being washed by a man on a crane shooting a water jet. “It’s romantic,” Dickinson said. “It’s this big floating helpful giant up there. It’s your mother’s arms holding you.”

It is difficult to compare airship enthusiasts, to rate who is the most passionate, but only one has written and recorded an eighteen-minute hard-rock ballad to an airship, backed by cellos and violins. “Empire of the Clouds,” on Iron Maiden’s latest studio album, “The Book of Souls,” is about Dickinson’s favorite airship, the R101, which was built a century ago, in this same shed in Bedford. It was meant to be Britain’s signature airship, a luxury liner outfitted with fifty carpeted cabins, two promenade decks, and a smoking room, and was designed to carry royalty across the sprawling British Empire. In 1930, on its maiden overseas voyage, the R101 crashed in a meadow east of Beauvais, France, and exploded in flames, killing forty-eight of the fifty-four people aboard.

Dickinson read about it when he was a kid. He built a model of the R101 and kept it on a shelf in his bedroom. In the nineteen-nineties, he met Roger Munk, a legendary British airship engineer, who told him about the Skykitten, a forty-two-foot-long remote-controlled prototype for his proposed Skycat hauler. “And I went, ‘So how are you doing, business-wise?’ ” Dickinson recalled. “He said, ‘Oh, we go bust about every ten days.’ And I said, ‘O.K. Right. Well . . . That’s clear.’ So I went up, found my wife, and said, ‘How much money do you think we could afford to just burn? Let’s imagine we put it in a bag, we put it out in the garden, and set fire to it. How much do you imagine that would be right now?’ ”

Dickinson gave Munk half a million dollars and helped spread the word. In 2010, Munk died unexpectedly, of a heart attack, just before it was announced that his Skycat design had been awarded a five-hundred-million-dollar contract from the U.S. Army. The Army wanted a surveillance ship that could fly twenty thousand feet above the war zone in Afghanistan for weeks at a time. The team in Bedford, under contract to Northrop Grumman, built the ship, and the Army named it the Long Endurance Multi-Intelligence Vehicle, or LEMV. On August 7, 2012, it made its first test flight, at Joint Base McGuire-Dix-Lakehurst, in Lakehurst, New Jersey, the same field where the Hindenburg exploded.

“It’s quite a big thing, you know,” Mike Durham, the Airlander’s technical director, told me. He had been Munk’s longtime deputy and felt his absence keenly. “It was the biggest aircraft to fly since 1960,” he said. But the budget sequestration in 2013 abruptly ended the Army’s experiment, and the blimp was auctioned for scrap. Hybrid Air Vehicles paid a little more than three hundred thousand dollars for it, dismantled it, packaged it in dozens of wooden crates, and sent it, by ship, back to Bedford.

Durham’s team has been rebuilding it as the Airlander 10, reattaching the fins, the engines, and the gondola, rewiring the avionics, and revamping it for the commercial market. Hybrid Air Vehicles has received a four-million-dollar grant from the British government, and another two and a half million dollars from an E.U. fund, and has about a thousand private shareholders, including Dickinson. The goal, Durham said, is to produce ten Airlander 10s a year for the next four years and then develop a fleet of Airlander 50s, a fifty-ton model.

When I asked about customers, I was directed to an independent study conducted by Renaissance Strategic Advisors, an aerospace-analysis firm, which describes a fifty-billion-dollar cargo market for airships. But Hybrid Air Vehicles was vague about who, exactly, was interested in buying one. The immediate aim was to get it in the air and dazzle people—to wake up the market. Dickinson hopes to one day take the Airlander to the North Pole and the South Pole in one go, live-streaming the journey on the Internet. “You just drop right down onto the ice cap,” he said. “Or drop right down on the Atacama Desert, and you go up through the rain forest or whatever, just for shits and giggles. You know?”

Durham appeared to feel the burden of being the one to usher in the age of lighter-than-air transport. “All I hope is that whoever is working in the world of L.T.A. doesn’t sod it up for everybody else,” he said. “A big accident now hurts us all. There are so many crazies out there.”

I asked him what he thought of Pasternak’s buoyancy-control system, COSH, and the rigid design.

“It’s Igor’s vision,” he said. “I wouldn’t say any more than that.”

The last time I visited Pasternak, in June, the Dragon Dream had been cleaned up, its fibre trusses scrapped, its silver skin bundled and pitched. “When you’re trying to change the world, sometimes the roof collapses,” he said. “It’s normal. It’s absolutely normal.”

We were again riding in the back of his S.U.V., having set off from his house, a Hollywood Hills mansion with an infinity pool dripping over the horizon. As Pasternak sees it, the contest is not about who can put on the best airship show but about which designer can meet the customer’s desire to lift, soar, and drop. The world needs an airship that can do its job without thick ropes, a water truck, or anything else. A rigid airship with a true buoyancy-control system was the total package. Anything less—the nonrigid Airlander, the LMH-1—was a partial solution.

“I mean, it’s much easier from an engineering standpoint,” Pasternak said. “You forget about customer for a second, you know what I mean? It’s more simple. It’s a kind of self-delusional process. It’s normal. We’re humans. You lock yourself in, and you become a victim of your own idea.”

His grand plan remains the same: to manufacture a fleet of sixty-six-ton, two-hundred-and-fifty-ton, and five-hundred-ton Aeroscraft cargo carriers. “Eighteen months’ delay,” he said of the Dragon Dream’s untimely end. “Maybe two years. It’s nothing.” But he no longer had a prototype to show investors; now he had a video of a prototype, some photographs, and a spreadsheet of answers to various engineering questions. Pasternak told me he is aiming for his fleet to be in global operation by 2023. It’s an ambitious goal, requiring him not just to find end users, such as a mining company that wants to send equipment to remote regions, but to configure and manage an entire airship-logistics network—transportation-leasing companies, insurance providers, financial firms.

“It’s not just money exchanged for a product,” Pasternak said. “You’re creating new ways.” He felt he was making progress: he had already enticed several cargo-transport companies, including Air Charter Service and Pacific Airlift, to sign memorandums of understanding, and his COSH system recently received a U.S. patent. Kazakhstan seemed interested. “A country that is landlocked,” he said. “Two options: build the infrastructure, or go with Aeroscraft and solve immediately.”

In the meantime, his surveillance-blimp business is thriving. A new, larger Sky Dragon, capable of carrying two thousand pounds of cameras and other spy equipment, just went into production. Customers in the Middle East are using Aeros equipment to monitor oil fields, and the Ukrainian government just signed a deal for an entire “integrated Ukrainian border-protection system.”

In the S.U.V., Pasternak reached for a cigar, brought it to his nose, and sniffed it. Cargo airships are not going to happen without outsized optimism—without at least one over-the-top zealous visionary thinking very, very big. “There is no plan B,” he said. “I need to achieve this mission.” Setbacks were inevitable. “We don’t know what we don’t know,” he said. “There was no roof going to collapse. How in the hell did roof collapse?” He kept on about the absurdity of the roof collapse, until he was swallowing his own laughter. “America,” he said. “America!” It was hilarious, he said, that a Ukrainian immigrant could come to America, penniless, and get more than fifty million dollars from the U.S. Department of Defense to build blimps in an old B-52 garage.

We were pulling into the Worldwide Aeros headquarters, and he had taken off his suit jacket. His white shirt pulled tightly across his belly. “Thank you very much,” he said, into the air, to his competitors. “I send you kisses and champagne.” They were, after all, selling the same thing. “I’m selling a dream,” he said. “I’m selling a promise. And when you are selling a promise you need proof you can deliver.

“You can call this gambling, or vision, or belief—whatever,” he went on. “Or knowledge. But, in reality, it’s contributing. I mean, we’re all asking the same question: what the hell we’re doing here. Right?” ♦

LINK: http://www.newyorker.com/magazine/2016/02/29/a-new-generation-of-airships-is-born