Holtec Wins the Turnkey Contract for Establishing the Dry Cask Storage Facility at Krško Nuclear Power Plant in Slovenia

Holtec International, Marlton, NJ

Holtec International, Marlton, NJ

Mon, Feb 27, 2017

|

We are pleased to announce the award of a severely contested contract for turnkey supply of a Dry Cask Storage Facility at Krško Nuclear Power Plant in Slovenia to Holtec International. NEK’s (Nuklearna Elektrana Krsko) initial decision to award the contract to Holtec in May 2016 was strenuously protested by Areva leading to nine months of independent expert reviews under the auspices of the country’s “National Review Commission”. “Slovenia’s process for an exhaustive and deliberative consideration of the aggrieved bidder’s representations is exemplary in respect of fairness and transparency. Unfortunately, the project schedule has been admittedly strained to accommodate this process,” says Dr. Richard Springman, Holtec’s Director of International Projects.

|

|

|

|

|

|

Schematic of Holtec’s HI-STORM FW System inside the Dry Storage Building

|

|

|

The contract scope includes design and construction of a Dry Storage Building (DSB), replacement of the fuel handling building crane trolley, and supply of the needed equipment and services to effectuate the dry storage implementation. The DSB is envisioned to be a fully equipped canister/cask handling facility with a state-of-the-art temperature and radiation monitoring system and the necessary equipment and systems to safely execute rarely needed activities such as severing a welded canister lid. The casks and storage facility will be licensed in Slovenia based on the USNRC 10CFR72 regulations, with additional performance criteria imposed by NEK to demonstrate safety against severe environmental phenomena and other 21st century hazards. NEK’s safety demonstration requirements are among the world’s most stringent, such as assured radiation safety in the wake of a crashing military or commercial aircraft impacting the casks and a postulated earthquake of an intensity exceeding any ever recorded on earth without toppling the casks (2.1 g’s in three dimensions). The DSB itself is designed for passive ventilation, a seismic pedigree of 0.78 g’s, and resistance to a flood level of over 2 m. To our knowledge, the safety requirements for this project collectively represent the most exacting combination of design conditions ever imposed on a spent fuel storage facility.

Holtec’s high capacity HI-STORM FW cask, already in use at several sites, won the technical aspects of the competition besting the competing bids in key performance areas, such as heat rejection capacity, survivability under extreme accidents, and transportability. Holtec’s high thermal capacity HI-STAR 190 transport cask will provide the flexibility for transport of the fuel off-site within seven years from the time of loading if a central storage or final disposal facility were to become available.

Holtec will fabricate the majority of the equipment at the Company’s state-of-the-art Heavy Manufacturing Plant at the Company’s Technology Campus in Camden, NJ. Holtec has partnered with local companies familiar with the Krško plant and local codes and standards for the civil work, supporting construction services, and for the supply of miscellaneous manufactured equipment.

|

|

|

|

For more information, please contact:

Erika Grandrimo - Publisher

Phone: +1 (856) 797-0900 ext. 3920 | Email: E.Grandrimo@holtec.com

|

|

|

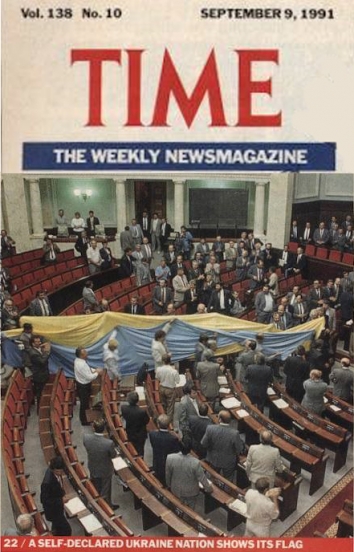

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

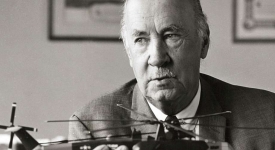

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

Ten USUBC Historic Full Page Ads in the Kyiv Post

Ten USUBC Historic Full Page Ads in the Kyiv Post

Holtec International, Marlton, NJ

Holtec International, Marlton, NJ