|

Oct 30, 2020

Max Polyakov posted a photo of the Alpha LV that will be used on the first flight. The design painted on its side resembles a phoenix, it was chosen as a metaphor for Firefly's recovery from bankruptcy.

|

|

|

|

Oct 29, 2020

Firefly is transitioning composite manufacturing to Ingersoll Automated Fiber Placement (AFP), which will enable Firefly to robotically fabricate all carbon-fiber structures of an Alpha rocket in fourteen days. The benefits include a 30-50% reduction in composite material waste, increased repeatability, reduced touch labor and build time, and reduced weight and overall costs. The first of two planned AFP systems will be installed in May 2021 at the facility in Briggs, Texas. Firefly's new Florida Space Coast factory and launch site at Cape Canaveral will house the second automated assembly line beginning 2022 and will ultimately be capable of producing an estimated 24 Alpha rockets per year, with the Briggs plant switching to automated developmental builds of the larger Beta LV.

|

|

|

|

Oct 28, 2020

Alpha Flight 1 payload fairing has passed the acceptance testing. The fairing separation system was designed and manufactured in-house and is “operationally resettable”, which means that each fairing can be fully tested prior to launch.

|

|

|

|

Oct 27, 2020

Firefly’s Vandenberg launch site team has successfully completed rotation testing of the strongback. It included verification of the launch pad hydraulic lift system and command and control from the blockhouse control room consoles.

|

|

|

|

Oct 21, 2020

Firefly currently plans for its maiden Alpha rocket launch to happen as early as Dec. 22, 2020, and as late as Jan. 13, 2021. Before launch, Alpha needs to pass the second stage engine test. Then Firefly will confirm that the ground systems are ready to go. After that, the rocket will be put on the launchpad and fueled up. Lastly, the static fire of the entire vehicle at the launch site will be performed. Within a day of that Firefly will go for launch. The second launch is scheduled five months after the first to resolve any issues that may arise. Firefly expects to launch at least three times in 2021.

|

|

|

|

Oct 20, 2020

Firefly has signed a Launch Services Agreement (LSA) with Spire Global for the launch of Lemur spacecraft on Alpha. The LSA will provide for the launch of Spire spacecraft on multiple Alpha missions over the contract period. Firefly has also executed an LSA with Geometric Space Corporation for the full payload capacity of an Alpha LV. Firefly is also nearing completion of its Launch Control Center, Integration Hangar, and launch pad, including assembly of the Transporter Erector Launcher (TEL) at Space Launch Complex 2 West at VAFB.

|

|

|

|

Oct 20, 2020

An article on CompositesWrld.com features an interview with Firefly engineers on Alpha design. Since re-opening the company in 2017, a new version of the rocket named Alpha 2.0 has been designed. The payload was increased from 300-500 kilograms to 1,000. The two-stage rocket is currently 95 feet tall, the payload segment is 6.6 feet in diameter and made from carbon fiber composite. Stage Two is 19.7 feet long, Stage One is 59.1 feet. Both stages comprise an exterior composite airframe and, inside, the oxygen, fuel and helium tanks, and avionics systems. With Alpha 2.0, Firefly switched to a turbopump-fed propulsion system that replaces the high-pressure tanks with motorized pumps. The tank and airframe are integrated into one continuous structure, which enables significant weight reduction for the rocket. As for materials, Firefly uses Toray carbon fiber prepregged with a proprietary epoxy resin system.

|

|

|

|

Oct 9, 2020

The Firefly Alpha Flight 1 Stage 1 passed its Final Acceptance Test. After a final inspection, it will be transported to Vandenberg Air Force Base in preparation for launch.

|

|

|

|

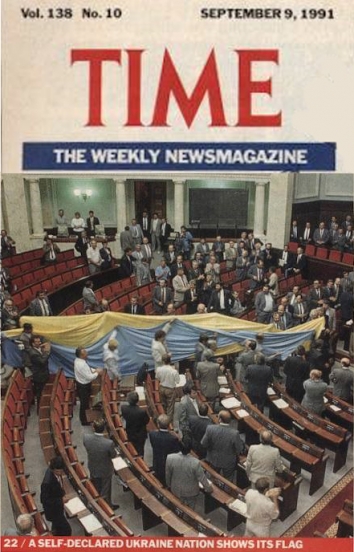

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

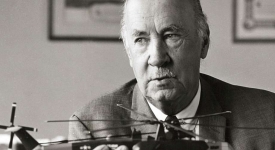

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

Ten USUBC Historic Full Page Ads in the Kyiv Post

Ten USUBC Historic Full Page Ads in the Kyiv Post

.jpg) FireFly Aerospace, Cedar Park,

FireFly Aerospace, Cedar Park,