|

We are pleased to announce that the first HI-TRAN 300, a vertical heavy load hauler designed by Holtec’s Nuclear Power Division (NPD) to serve as the single-failure-proof workhorse for hauling loaded Holtec dry spent fuel storage system components and for executing inter-cask canister transfer, has been successfully manufactured and factory tested by the Company’s Advanced Manufacturing Division in Camden, New Jersey. HI-TRAN 300 is also envisioned to transport heavy loads at Holtec’s SMR-160 plant currently undergoing regulatory review in Canada and the HI-STORE Consolidated Interim Storage Facility being developed by Holtec in New Mexico.

|

|

|

|

HI-TRAN’s development was undertaken to solve the transporter reliability problems procured from third parties that occasionally have plagued some dry store campaigns in the industry. HI-TRAN is built as a safety-significant machine and has certain unique reliability features that differentiate it from other machines sold in the industry. For example, it has four hydraulic lifters (in lieu of two, commonly used in the industry) with a total rated lift capacity of 300 tons.

|

|

|

|

|

|

The HI-TRAN 300 at AMD Prior to Disassembly and Shipment Where It Will Then be Reassembled and Painted

|

|

|

|

|

Artist's Rendering of the HI-TRAN 300

|

|

|

Weighing 267,000 lbs. when empty, HI-TRAN 300 is an imposing machine that strides on two parallel caterpillars to minimize ground pressure and has zero turn radius. It boasts a rated capacity of 300 tons, which is sufficient to haul the heaviest loaded cask supplied by Holtec. Its vertical stroke can be variable depending on service requirements. For example, if used in cask stack-up, HI-TRAN’s vertical range can be as much as 330 inches.

|

|

|

|

|

|

The First HI-TRAN 300 is Pictured Along with the

Proud Team Who Conceived and Built It

|

|

|

he architect behind the development of HI-TRAN 300, NPD Design Manager, Leyland Vann, said, “It’s been an honor to work on a project that provides a reliable solution to the industry and I look forward to building many more HI-TRANs for the industry.” The successful development and deployment of HI-TRAN 300 completes our program of redesign of key ancillary devices to improve their operational reliability. It also eliminates reliance on subcontractors during cask loading campaigns.

|

|

|

|

|

|

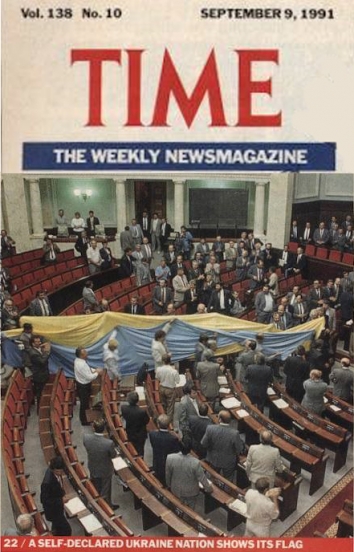

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

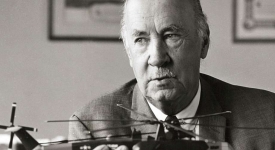

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

Ten USUBC Historic Full Page Ads in the Kyiv Post

Ten USUBC Historic Full Page Ads in the Kyiv Post

Holtec, Camden, USA

Holtec, Camden, USA