USDOE Announces Financial Support for Holtec’s Advanced Laser Welding Process for New and Operating Reactors

Holtec, Marlton, NJ

Holtec, Marlton, NJ

Fri, July 13, 2018

|

We are pleased to announce that the USDOE has accepted Holtec’s proposal to advance and commercialize a cutting-edge technology known as hybrid laser arc welding for use in nuclear structures and systems. Our own SMR-160 small modular reactor program will be a principal beneficiary of the fruits of this R&D program. We anticipate that this advancement will help improve the quality of welds in the entire range of critical service components, from thick-walled reactor vessels to thin-walled multi-purpose canisters. Brian Farnsworth, Holtec’s principal subject matter expert and noted innovator of welding and non-destructive examination technologies, stated, “this project will allow us to investigate and develop very low weld heat input techniques coupled with grain size control (refinement), mechanical properties optimization, high joint fill rates utilizing narrow gap, and very close control of weld heat-affected zone size.”

|

|

|

|

|

|

Advanced Robotic Welding Technology

|

|

|

“We thank Secretary Perry and the leadership of DOE’s Office of Nuclear Energy, for supporting our innovative proposal. This will have far reaching consequences to the advancement of welding of critical mission components in the nuclear industry and will contribute to the success of the US Small Modular Reactor program. We look forward to working with our partners Sandia National Laboratory, Lincoln Electric, and Edison Welding Institute,” says Myron Kaczmarsky, Senior Director of Holtec Government Services.

Offering quality welds in plant’s pressure vessels, the hybrid laser arc welding development program brings Holtec one step closer to achieving a 100-year service life SMR-160 nuclear plant. In this respect, the DOE’s support will likely have an impact far beyond its modest dollar value of $6.3 million.

Holtec International employs hundreds of welders and mechanics in each of its heavy manufacturing plants in Pittsburgh, PA and Camden, NJ and the light manufacturing plant in Orrville, Ohio. The Company has introduced several cutting-edge welding processes in recent years, such as friction stir welding and robotic narrow groove welding, to maintain its technical leadership in the global manufacturing technology race. “A strong, supple and innovation-fueled welding program is an essential ingredient of the continuing success of our nuclear undertakings to which the DOE’s award is a timely elixir of support,” says Holtec’s Chief Communications Officer, Ms. Joy Russell.

|

|

|

|

For more information, please contact:

Erika Grandrimo, Publisher

Phone: (856) 797-0900, ext. 3920 | Email: e.grandrimo@holtec.com

|

|

|

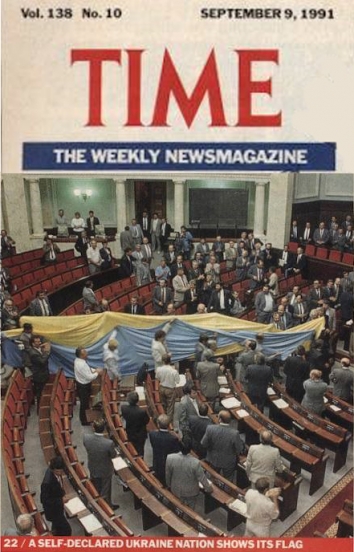

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

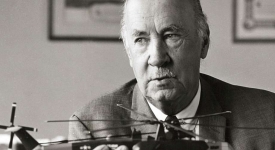

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

Ten USUBC Historic Full Page Ads in the Kyiv Post

Ten USUBC Historic Full Page Ads in the Kyiv Post

Holtec, Marlton, NJ

Holtec, Marlton, NJ